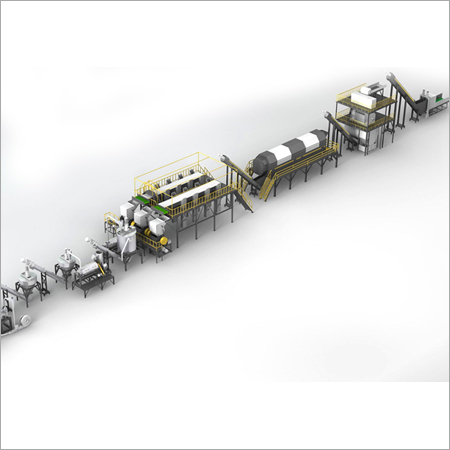

PE And PP Recycling Line

PE And PP Recycling Line Specification

- Product Type

- Plastic Recycling Line

- Material

- PE, PP (Polyethylene, Polypropylene)

- Capacity

- 150-1000 kg/h

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Processing Type

- Recycling Machine

- Voltage

- 380V, 50Hz, 3 Phase (customizable)

- Power

- 55-120 kW (depending on model)

- Dimension (L*W*H)

- 22000 x 3000 x 2500 mm (approx., varies by model)

- Weight

- 12-25 Tons (varies with configuration)

- Color

- Blue/White (customizable)

About PE And PP Recycling Line

New release: The first-rate PE And PP Recycling Line brings formidable recycling efficiency to your operations! Designed to process PE/PP films, woven sacks, bottles, and bags, this best-in-class line adapts with either single or double screw extrusion. Choose from strand, water-ring, or die-face cuttingeach setup tailored to your requirements. Take advantage of its automatic PLC control, 150-1000 kg/h capacity, and low operator requirement. Add to cart and experience robust performance, after-sales service, and customizable options for color and voltage. Exported worldwide from a leading Chinese manufacturer, supplier, and exporter.

Applications & Competitive Advantages

The PE And PP Recycling Line is ideal for recycling polyethylene and polypropylene films, bottle scraps, woven sacks, and bags. Its application area spans packaging industries, commercial recycling plants, and waste management facilities. Notable competitive advantages include automated PLC operations, customizable screw/pelletizing designs, and moisture content tolerance up to 5%. Experience superior material compatibility and high capacity, making this line a formidable choice across various surfaces and recycling needs.

Sample Availability, Market Reach & Delivery

Sample units of the PE And PP Recycling Line are available to prospective clients. The main domestic market covers China, but with robust logistics and a well-developed export network, supplies reach major international markets too. As a trusted exporter, distributor, and supplier, we ensure reliable delivery times to suit your operational schedules. Take full advantage of professional logistics support and prompt shipment, whether for small test orders or full-scale operational supply.

Applications & Competitive Advantages

The PE And PP Recycling Line is ideal for recycling polyethylene and polypropylene films, bottle scraps, woven sacks, and bags. Its application area spans packaging industries, commercial recycling plants, and waste management facilities. Notable competitive advantages include automated PLC operations, customizable screw/pelletizing designs, and moisture content tolerance up to 5%. Experience superior material compatibility and high capacity, making this line a formidable choice across various surfaces and recycling needs.

Sample Availability, Market Reach & Delivery

Sample units of the PE And PP Recycling Line are available to prospective clients. The main domestic market covers China, but with robust logistics and a well-developed export network, supplies reach major international markets too. As a trusted exporter, distributor, and supplier, we ensure reliable delivery times to suit your operational schedules. Take full advantage of professional logistics support and prompt shipment, whether for small test orders or full-scale operational supply.

FAQs of PE And PP Recycling Line:

Q: How does the PE And PP Recycling Line manage different types of plastic feedstocks?

A: The line is engineered for versatility, efficiently processing PE/PP films, woven sacks, bottles, and bags using customizable single or double screw designs and multiple pelletizing options.Q: What is the operator requirement for running the recycling line?

A: It requires only 2-3 operators per shift, maximizing efficiency while minimizing labor needs, thanks to its automated PLC-controlled system.Q: When is after-sales support available for this equipment?

A: After-sales service is offered globally, with engineers readily available to service the machinery and provide technical support whenever needed.Q: Where are the PE And PP Recycling Lines manufactured and supplied from?

A: These recycling lines are produced and shipped from China, supported by a reputable network of distributors and exporters.Q: What are the primary benefits of using this recycling line in an industrial setting?

A: The system delivers high throughput (150-1000 kg/h), low water consumption, consistent moisture tolerance, and design flexibility, ensuring cost-effective, reliable recycling operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plastics Recycling Machine Category

Pet Recycling Line

Dimension (L*W*H) : Customized

Capacity : 5001000 kg/hr

Product Type : Pet Recycling Line

Warranty : 1 Year

Automatic Grade : SemiAutomatic

Control System : PLC Based, Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry